Beautiful and Durable

We’ll contact you via phone, email, or text to discuss your garage upgrade.

We install garage floor coatings for homes that are both beautiful and tough. Choose from a wide range of garage flooring styles and finish options. When it comes to garage floor coatings in Nashville, looking great is only the start. Our garage floor coatings are far more durable than traditional epoxy coating. It won’t chip, peal, or wear away, and it’s also easy to care for so you can keep it always looking great.

Get your garage back in order in notime so you can start to enjoy your beautiful new floor right away.

Most Floors Completed in Just 1-Day with Superior Results

Step One:

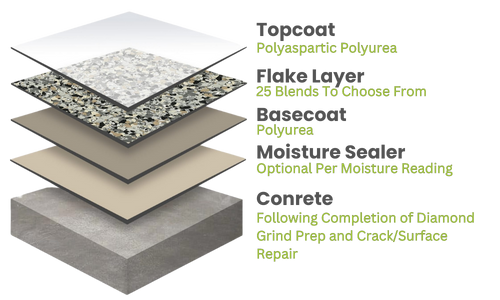

We use diamond tip grinders to completely clean and prepare the concrete. Each crew carries a full range of diamond tooling so they can adapt to every type of concrete. This important step is vital in creating the proper surface for a durable bond and is a prime differentiator between our process and many other vendors in the market. After this first step, the concrete is like a sponge with a textured surface – ready to absorb and lock in the base layer of polyurea material and create a durable bond.

Step Two:

We test all floors for moisture content, applying a separate seal coat as needed. If more than one portion of the floor tests high, we will recommend a moisture sealer by applied to the entire floor. While this moisture sealer adds a day to our process, we will not rush a job; ensuring that your floor will stand up to the challenging weather conditions.

Step Three:

For any cracks, divots, or minor imperfections, we use an advanced, fast-curing polymer patching material to create a smooth surface. (Please note that we do not typically fill existing open expansion joints and strongly recommend that they remain in place).

Step Four:

We then apply a pigmented base coat of our industrial-grade polyurea or epoxy to create the strongest possible bond with the exposed concrete surface. This material is considerable stronger than typical epoxy– it is also more flexible which means unlike typical epoxy it will not become brittle and shift which can cause peel and lift after only a short time. While there are several alternatives currently available, our rated above the adhesion strength of typical epoxy.

Step Five:

While the base coat is still wet, we completely cover the floor with a full broadcast of colored PVC flakes giving the floor its dynamic pattern. The polyurea base coat holds the flakes and begins to cure via chemical reaction. A monolithic bond is formed between the polyurea and the concrete, while at the same time creating a similar bond with the PVC flake layer. This forms the lasting foundation of our system. While we have a variety of different colored flake blends in stock and ready to go, your choices are truly endless. For a small up charge, we can custom blend flakes to create the perfect look for your garage floor.

Step Six:

Once cured, the excess flakes are scraped away to reveal the “orange peel” texture of the floor. Because we broadcast a thick layer of flakes on Day 1, our finished product achieves 95-98% coverage.

Step Seven:

The final step or our process is to broadcasting slip resistant grit into the clear top coat. This grit provides additional texture to increase the safety of the surface when wet.

Optimus Garage is your floor-to-ceiling, single-source provider for the highest quality floor coatings, garage-grade cabinets, wall storage, and car lifts. With an entire team of professionals standing by to assist you every step of the way, Optimus Garage is your best choice for your garage transformation!

© 2023 Optimus Garage; All Rights Reserved;

Proudly founded in Nashville, TN

Handcrafted by ![]() Dream Digital Partners

Dream Digital Partners